Registered with the Registrar of Newspapers for India under R.N.I 53640/91

Vol. XXV No. 20, February 1-15, 2016

Madras Checks

A historic fabric

Handlooms have been part of the rhythm of life in India and belong to an industry which is second only to agriculture. Indian textiles have created turning points in history. Gandhiji “cremated” foreign fabric in an act of defiance, collecting them from sophisticated Indians who wanted to be on the same page as the British. It drained the British coffers and marked the beginning of the end of colonial rule.

Again, it was handlooms that moved Francis Day into choosing Madras as the new British settlement. He was impressed with Madras “being the only place for paintings, and a great store of longcloath and morrees.” He was, of course, referring to hand block-printed chintz, and morrees was blue cotton cloth. On his return from a tour of the Coromandel Coast, he was showed around by the local Naik, Damarla Venkatadri. Day met merchants, painters and weavers, examined a variety of fabrics and what impressed him was the price, as cloth was 15 per cent cheaper than that at Armagaon (Durgarayapatnam) about 35 miles north of Pulicat. Calico was in great demand, but that which was produced at Armagon was of poor quality so a new settlement had to be found. Francis Day decided on the new settlement… Madraspatnam. The rest is history. As historian Sriram once said, “Madras was founded not for spices and gold but for cloth.”

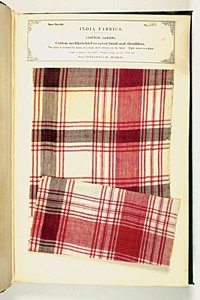

Madras in cotton from 1866

Madras in cotton from 1866Harris Museum.

Woven in 60×40 handloom, with variations in stripes or solid squares, the fabric is known by many different names: Madras Checks, real Madras Handkerchief, George cloth and Guinea cloth, Bleeding Madras. Call it what you will, but this simply designed fabric still continues to excite wearers.

Why Bleeding Madras? Every time it is washed the colour bleeds and it assumes a new avatar without looking faded or dull. The warp was generally dyed in indigo and turmeric used for yellow. And the indigo base combined with yellow produced green that ran on the weft when soaked in water creating new shades and solid colours,

The RMHK (Real Madras Handkerchief) was a term coined by British merchants to describe the 8-metre long, 36 inches wide bolts of fabric which could be cut into three square kerchiefs. It was a successful ploy which helped exporters evade taxes as it was bales of fabric which entered London. It was in 1800s that plaids came into fashion, and it is believed that the patterns were copied from the tartan plaids of the Scottish regiments that were in Southern India in the 1800s. It is also said that the tartan craze began with the visit of King George IV to Scotland in 1822.

Textile scholar Jasleen Dhamija suggests that plaid handlooms existed in southern Andhra Pradesh and Madras hundreds of years before the British arrived. She points to the 16th Century Portuguese records which describe the popularity of the checked scarves, or rumaals, among the Haj pilgrims, claiming that these rumaals originated in Masulipatnam, and were woven as ritual textiles for cleaning the faces of the temple deities prior to the Persian and Arab traders who took them back to Mecca.

Madras Checks always in fashion.

Madras Checks always in fashion.

Trade routes carried the plaid cloth into West Africa where Madras was used mainly for turbans and, later, became a totemic commodity among the Kalabari tribe in the Niger delta. Design scholar Sandra Lee tells us that the Madras checks arrived via the Portuguese maritime trade routes. By the 18th Century, the fabric was a valued commodity in the trans-Atlantic slave trade well into the nineteenth century.

The Madras handkerchief was exported to London where it would be auctioned to traders who used it as an item for barter for slaves in West Africa. RMKH reached the Caribbean and South America where it was used as headscarves among black women.

At the turn of the 20th Century, two European companies, A. Brunnschweller & Co. and Coles Son & Co., dominated the RMHK trade. The cloth was shipped through Manchester and London and auctioned to the trading firms. A.B& Co. opened an office in Madras in 1907 bypassing London altogether. Indian firms began to enter the arena, and the first traders were Sindhis.

For 400 years, the Kalabari, a small group of Ijo ethnic people in Nigeria, have been trading in the RMHK. The community was fused, as it were, with Indian textiles in daily and ceremonial life. Anthropologists Eisher and Erekosima explain that Madras fabric has a special presence in Kalabari life and is a symbol of a person’s journey from the womb to the tomb. Kalabaris call the fabric Injiri. It is part of the ceremony of the veneration of life, so much so that the brides of West Africa, the Gold Coast and Ghana sought to have their gowns tailored from Madras Checks in the early 18th and 19th Centuries.

Madras checks cloth forms an integral part of the funeral ceremony for the Kalabaris, and the cloths used for this purpose are called ede deis, when the walls and ceilings of the room are lavishly decorated. The cloths are preserved and loaned to others who would need them. The family status is assessed by the number, type and age of these cloths.

In contemporary use, Madras checks, thanks to the preppy world’s love for the unusual and to brilliant marketing, have become a mark of affluence. Imitation plaids, machine-made, were manufactured in Japan, Switzerland, England and France.

Madras Checks – much sought after in West Africa

Madras Checks – much sought after in West Africa

In the 1960s the popularity of Madras checks peaked. In the Nigerian market, handloom checks were still imported under the name of Real Madras Handkerchief. In the 1970s, Nigieria imposed a ban against a variety of goods due to political instability and the market for import of RMKH collapsed.

Bleeding Madras was made popular by Capt C.P. Nair, founder of the Leela Group. In the 1950s, Capt Nair showed an American exporter a fabric which was woven in Chennai for South Africa using natural dyes, and one which would run and change form after every wash. The exporter ordered 10,000 yards and the cloth was tailored into stylish garments and sold at Brooks Brothers, New York

The exporter threatened to sue Capt Nair when the fabric really bled, and Nair pointed out that he had warned him earlier. When the editor of Seventeen Magazine ran a story on Bleeding Madras, the first order was that of a million yards. They were woven all over Tamil Nadu, and then in Andhra Pradesh.

Resuscitating the market for handloom from Madras would mean bringing in the textile’s cultural history and re-introducing it to the place that gave birth to it, not in another form like sarees or lungis but as a fashion fabric which would find its niche in a global luxury market place.

Sabita Radhakrishnan

Pingback: Bleeding Madras Check & the sari from Maheshwar #AtoZChallenge 2017 | Mumbai On A High